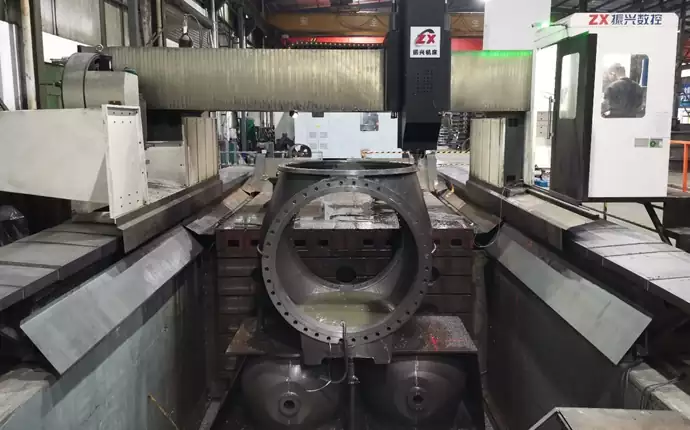

5-Axis Machining Center

Complex flow channels and multi-face forming in a single setup reduce cumulative errors and improve contour and positional accuracy.

- Online probe for first-piece verification

- Controlled tool compensation and program versions

- Unified process benchmarks