1. Product Overview

Alternate Names: B2F Double Flange Restrained Expansion Joint, Double Flange Expansion Compensator

Application Scenarios: Suitable for pipeline systems with flanged connections at both ends. It compensates for axial displacement through expansion and contraction while limiting excessive deformation, protecting pipeline equipment from damage caused by thermal expansion and contraction, foundation settlement, and vibration stress.

Functional Positioning:

Displacement Compensation: Allows the pipeline to expand and contract freely within a specified range (± expansion amount), compensating for axial displacement caused by temperature changes, installation deviations, or foundation settlement. (Cannot absorb lateral or angular displacement)

Restraint Protection: Limits excessive stretching or compression through bolts and nuts that lock the maximum expansion range, preventing leakage, structural damage, or equipment overload.

Simplified Installation: Facilitates the installation and maintenance of valves, pumps, and other equipment by providing flexible adjustment space and reducing alignment difficulty.

Thrust Reduction: Distributes blind flange force (internal pressure thrust) during pipeline operation, reducing direct stress impact on equipment.

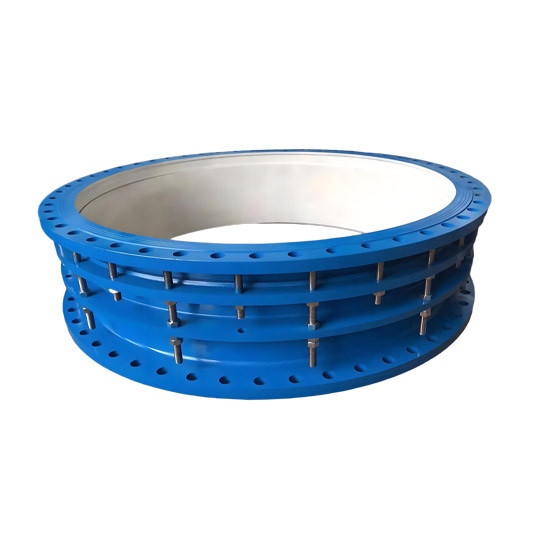

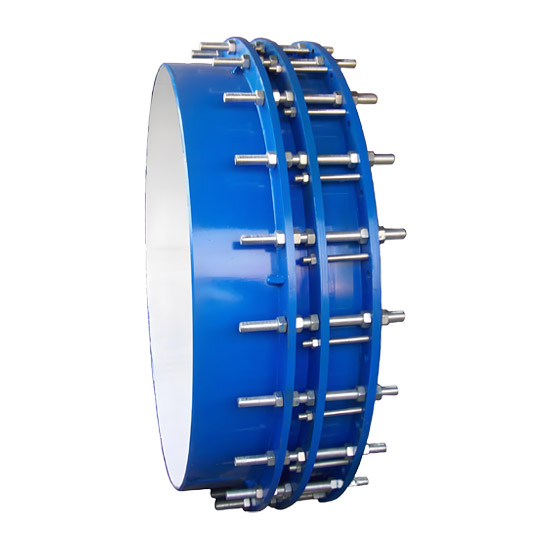

Structural Components:

Body: Cylindrical housing made of carbon steel (Q235A), ductile iron (QT400-15), or stainless steel (304/316), providing pressure resistance and expansion support.

Sealing Ring: Trapezoidal NBR rubber ring, hardness 60±5 Shore A, oil-, water-, and temperature-resistant (-40°C to 80°C under standard conditions; special seals available for ≤250°C steam and other media), ensuring reliable sealing.

Gland: Made of the same material as the body, tightened by bolts to compress the sealing ring and form a sealing surface.

Restraint Device:

Restraining Short Pipe: One end welded to the pipeline flange or directly to the pipe (depending on design), the other end bolted to the body flange.

Restraint Bolt Assembly: Full-thread bolts with double nuts connecting the body and restraining pipe. Nut position adjustment sets the maximum expansion range and locks it rigidly.

Flanges: Both ends use flanges compliant with GB/T 9115 (PN0.6~PN2.5MPa) or ASME B16.5 (Class 150/300), enabling pipeline connection.

2. Design and Manufacturing Standards

2.1 Design Specifications

Basic Standards: Strictly follows GB/T 12465-2007 “Loose Sleeve Expansion Joints for Pipelines” (replacing GB/T 12465-2002), defining structural dimensions, expansion range, pressure performance, and compensation mechanism requirements.

Refers to GB 50268 “Code for Construction and Acceptance of Water Supply and Drainage Pipeline Works” for force calculations, support layout, and installation spacing recommendations.

Metal strength design complies with GB/T 150 “Pressure Vessels,” ensuring strength and stability of pressure pipeline components.

Material Selection Standards:

Body / Flanges:

Carbon Steel (Q235A): Complies with GB/T 700 “Carbon Structural Steel,” ensuring structural strength and cost-effectiveness.

Ductile Iron (QT400-15): Complies with GB/T 1348 “Ductile Iron Castings,” suitable for corrosion resistance and vibration tolerance.

Stainless Steel (304/316): Complies with GB/T 1220 “Stainless Steel Bars,” suitable for highly corrosive media such as seawater and chemical fluids.

Sealing Ring: NBR rubber complies with HG/T 2579 “Oil-Resistant Rubber Sealing Materials,” with designed hardness ensuring sealing and media resistance.

Restraint Bolts / Nuts: Carbon steel hot-dip galvanized (zinc layer ≥85μm, GB/T 13912) or stainless steel, compliant with GB/T 3098.1 “Mechanical Properties of Fasteners,” ensuring tensile strength and preventing failure.

Expansion Range Design: Based on nominal diameter (DN) and pressure rating (PN), typical expansion range is ±(20~65mm) (e.g., DN100: ±50mm; DN1000: ±65mm). Specific values must comply with manufacturer specifications and GB/T 12465 standards.

2.2 Manufacturing Process and Quality Control

General Production Standards: Quality management system follows GB/T 19001-2016, covering raw material inspection, machining, assembly, and final inspection.

Body machining precision complies with GB/T 1804 grade m tolerance (for unspecified linear dimensions), ensuring component fit accuracy.

Key Process Standards:

Welding Process: Restraining pipe welded to flange/pipe according to GB 985.1 “Recommended Weld Groove.” Weld strength ≥ base material. Post-weld stress relief applied. Pressure-bearing welds inspected per JB/T 4730.2 “Radiographic Testing,” Grade I qualified.

Surface Treatment: Carbon steel parts hot-dip galvanized (zinc layer ≥85μm, GB/T 13912); stainless steel parts pickled and passivated or coated with corrosion-resistant layer.

Paint adhesion test complies with GB/T 1720 ≥ Grade 2, ensuring long-term corrosion protection.

Assembly and Adjustment: Sealing ring installed with uniform compression; restraint bolts pre-adjusted to factory installation length (expandable state), preventing transport damage.

Factory Inspection:

Pressure Test: Each product undergoes hydrostatic testing at 1.5× nominal pressure for 30 minutes with no leakage, compliant with GB/T 13927 “Industrial Valve Pressure Testing.”

Performance Verification:

Expansion Function Test: Manual expansion of the body to check flexibility, ensuring no jamming or abnormal resistance.

Restraint Reliability: Adjust restraint nuts to maximum expansion range and simulate working conditions to verify locking effectiveness.

Tensile Test of Thrust Bolts: Random inspection of bolt assemblies for mechanical performance per GB/T 3098.1.

3. Technical Specifications and Parameters

Nominal Diameter (DN): DN32 ~ DN4000 mm (covers standard pipeline systems)

Working Pressure Rating: PN0.6, 1.0, 1.6, 2.5 MPa (custom high-pressure options available upon request)

Applicable Temperature:

Standard Media: -40°C ~ 80°C (NBR seal)

High-Temperature Conditions (steam, etc.): ≤250°C (requires FKM or metal-graphite composite seal)

Applicable Media: Fresh water, seawater, wastewater, crude oil, fuel oil, lubricating oil, air, coal gas, steam ≤250°C, and particulate/powdered fluids

Flange Connection Standards:

Domestic Projects: GB/T 9115 (PN0.6~PN2.5MPa), RF raised face (PN0.6/1.0) or MFM male-female face (PN1.6/2.5)

International Projects: ASME B16.5 (Class 150/300), must be specified in order notes

Installation Length and Expansion Range:

Factory Installation Length: Determined by DN (e.g., DN500: total length approx. 580mm)

Allowable Expansion Range: ±(20~65mm), specific values per manufacturer’s technical specification

Materials and Corrosion Protection:

Body / Gland: Carbon steel (hot-dip galvanized), ductile iron (plastic-coated), stainless steel

Restraint Bolts / Nuts: Carbon steel hot-dip galvanized or stainless steel, corrosion protection level matched to system environment

4. Operating Principle

Displacement Compensation Mechanism: When axial displacement occurs due to temperature changes (thermal expansion/contraction), foundation settlement, or mechanical vibration, the body slides freely within the restraint range via the expansion pipe, absorbing displacement energy and preventing stress concentration at equipment interfaces.

Restraint Protection Principle: By adjusting the nut position on the restraint bolts, the maximum allowable expansion is set (typically centered at factory installation). When displacement reaches the limit, the restraint bolts contact the flange, forming rigid support to prevent over-expansion and avoid pipe pull-out or collapse.

Sealing and Thrust Transmission: Diagonal tightening of gland bolts compresses the sealing ring to form a reliable seal. Flange bolts and restraint components distribute pipeline thrust across the system, reducing blind flange force impact on equipment.

Hot Tags: Expansion Joint / Compensator /