1. Product Overview

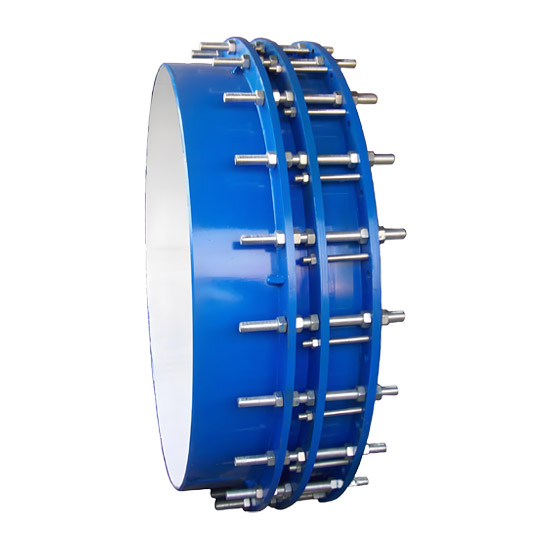

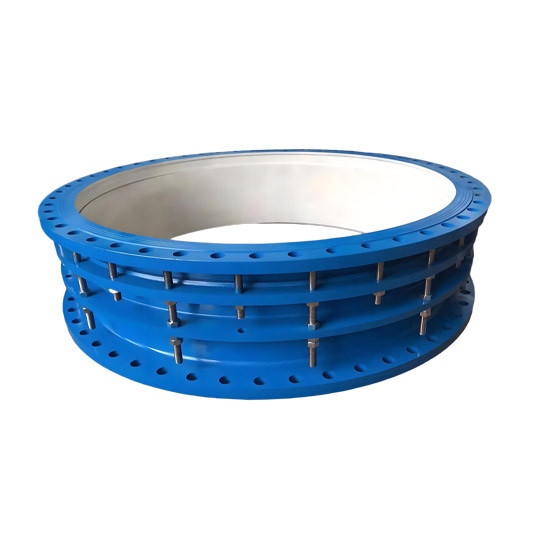

Full Name: VSSJAFG (CF) Type Single Flange Loose Sleeve Force Transfer Joint

Alternate Names: CF Single Flange Force Transfer Compensator, Single Flange Force Transfer Expansion Joint

Standard Compliance: Conforms to GB/T 12465-2007 “Loose Sleeve Expansion Joints for Pipelines” and relevant industry specifications.

Functional Positioning:

Axial Thrust Transmission: Distributes blind flange force caused by internal pressure fluctuations or thermal expansion throughout the system, protecting pumps, valves, and other equipment from concentrated stress damage.

Installation Error Compensation: Allows length adjustment during installation to compensate for pipeline dimensional deviations, facilitating on-site flange alignment.

Rigid Connection: During operation, the joint is rigidly locked at both ends via force transfer bolts. It does not absorb axial displacement during service (distinct from restrained expansion joints).

Structural Composition:

Body: Cylindrical housing made of carbon steel (Q235A), ductile iron (QT400-15), or stainless steel (e.g., 304).

Sealing Ring: Trapezoidal NBR rubber ring providing reliable sealing performance.

Gland: Same material as the body, bolted to compress the sealing ring and form a seal.

Restraining Short Pipe: One end welded to the pipeline, the other bolted to the body flange, allowing installation length adjustment.

Force Transfer Bolt Assembly: Full-thread bolts and nuts connecting both flanges to transmit mechanical force.

2. Technical Specifications and Parameters

Nominal Diameter (DN): DN32 ~ DN4000 mm (covers standard pipeline systems)

Working Pressure Ratings: 0.6 MPa, 1.0 MPa, 1.6 MPa, 2.5 MPa (selected according to design requirements)

Applicable Temperature:

Standard Conditions: -40°C ~ 80°C

Special Conditions (e.g., steam): ≤250°C (requires confirmation of sealing material and structural design)

Applicable Media: Fresh water, seawater, hot/cold water, drinking water, wastewater, crude oil, fuel oil, lubricating oil, air, coal gas, and steam ≤250°C

Flange Standards:

Connection Flanges: Compliant with GB/T 9115 “Steel Pipe Flanges” (PN0.6~PN2.5 MPa) or ASME B16.5 (Class 150/300), compatible with mating flanges

Installation Method: One end welded to the pipeline, the other end flanged (distinct from VSSJAF type with flanges on both ends)

Materials and Corrosion Protection:

Body / Gland: Carbon steel (hot-dip galvanized, zinc layer ≥85μm per GB/T 13912), ductile iron (plastic-coated), stainless steel (for corrosive environments)

Force Transfer Bolts / Nuts: Carbon steel (hot-dip galvanized) or stainless steel (e.g., 35#, 1Cr18Ni9Ti), compliant with GB/T 3098.1 “Mechanical Properties of Fasteners” for tensile strength

Compensation Characteristics: Used only for length adjustment during installation (minor displacement compensation); rigidly locked during operation with no displacement absorption

3. Design and Manufacturing Standards

(1) Design Specifications

Basic Design: Follows GB/T 12465-2007 for structural dimensions, pressure capacity, and force transfer mechanism, ensuring effective distribution of blind flange force

Refers to GB 50268 “Code for Construction and Acceptance of Water Supply and Drainage Pipelines” for force calculations and support layout recommendations

Metal strength design complies with GB/T 150 “Pressure Vessels” for pipeline component integrity

Material Selection:

Carbon Steel Body: Complies with GB/T 700 “Carbon Structural Steel,” ensuring mechanical performance of body and flange

Sealing Ring: NBR rubber with hardness 60±5 Shore A, oil- and media-resistant, compliant with HG/T 2579 “Oil-Resistant Rubber Sealing Materials”

(2) Manufacturing Process

General Production Standards: Follows GB/T 19001 Quality Management System, covering raw material inspection, welding, assembly, and final testing

Body Machining Precision: Complies with GB/T 1804 grade m tolerance (for linear dimensions without specified tolerances)

Key Processes:

Welding: Restraining short pipe welded to pipeline per GB 985.1 “Recommended Weld Groove,” weld strength ≥ base material; post-weld stress relief applied; pressure-bearing welds inspected per JB/T 4730.2, Grade I radiographic testing

Surface Treatment: Carbon steel parts hot-dip galvanized (zinc layer ≥85μm, GB/T 13912); painted parts tested for adhesion ≥ Grade 2 (GB/T 1720)

Factory Inspection:

Hydrostatic Test: Each product undergoes pressure testing at 1.5× nominal pressure for 30 minutes with no leakage (compliant with GB/T 13927 “Industrial Valve Pressure Testing”)

Tensile Test for Force Transfer Bolts: Mechanical performance verified per GB/T 3098.1

4. Operating Principle

Force Transfer Mechanism: When axial thrust is generated by internal pressure changes or thermal expansion, the force is evenly transmitted through the force transfer bolts across the system, preventing pumps, valves, and other equipment from bearing direct impact loads

Installation Adjustment: By adjusting the spacing between the restraining short pipe and flange, installation deviations in pipeline interface dimensions are compensated, facilitating bolt hole alignment

Sealing and Rigid Locking: Gland bolts are evenly tightened diagonally to compress the sealing ring and form a seal; force transfer bolts rigidly connect both ends, ensuring mechanical force transmission without displacement during operation

Hot Tags: Expansion Joint / Force Transfer Joint / Compensator /