1. Product Overview

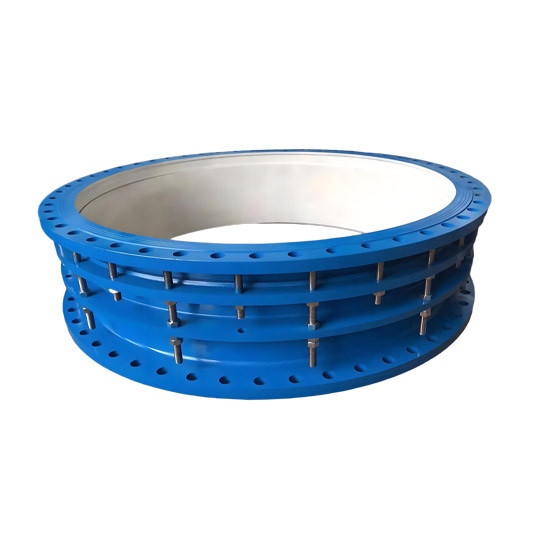

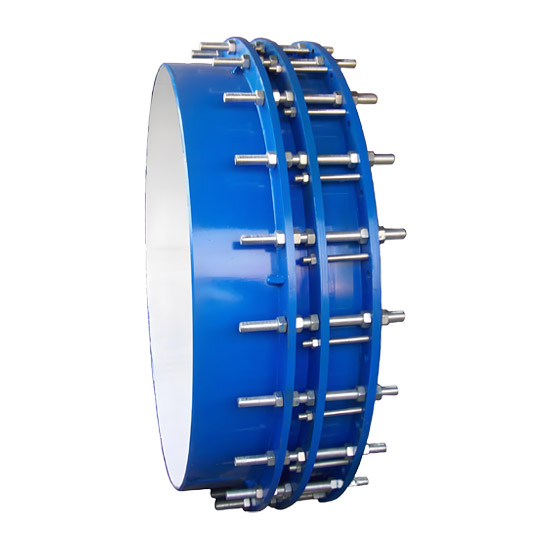

Full Model Name: VSSJAF (C2F) Type Double Flange Loose Sleeve Force Transfer Joint

Alternate Names: Double Flange Expansion Joint, Force Transfer Compensator, Double Flange Force Transfer Compensator

Standard Compliance: Conforms to GB/T 12465-2002 or relevant industry specifications

Used in pipeline systems to transmit axial thrust (blind flange force), preventing valves, pumps, and other equipment from bearing excessive pressure and ensuring equipment safety.

Compensates for installation deviations and minor displacement, facilitating installation and maintenance adjustments.

Transfers mechanical force through rigid connection, ensuring pipeline system stability.

Structural Components:

Body: Made of carbon steel (Q235A), ductile iron (QT400-15), or stainless steel (e.g., 304)

Sealing Ring: Made of nitrile rubber (NBR), ensuring sealing performance and media resistance

Gland: Same material as the body, bolted to compress the sealing ring

Expansion Short Pipe: Adjusts installation length and allows limited displacement

Force Transfer Bolt Assembly: Connects both flanges and transmits axial thrust across the pipeline system

2. Technical Specifications and Parameters

Nominal Diameter (DN): DN65 ~ DN3200 mm (covers standard pipeline sizes)

Working Pressure Ratings: Standard types: 0.6 MPa, 1.0 MPa, 1.6 MPa, 2.5 MPa (subject to manufacturer or design selection)

Applicable Temperature:

Standard Conditions: -40°C ~ 80°C

Special Media (e.g., steam): ≤250°C (requires confirmation of sealing material and structural design)

Applicable Media: Fresh water, seawater, hot/cold water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, refined oil, air, coal gas, granular and powdered media, and steam not exceeding 250°C

Flange Standards: Designed according to GB/T 9115 or ASME B16.5, compatible with mating flange connections

Materials and Corrosion Protection:

Body / Gland: Carbon steel (hot-dip galvanized), ductile iron (plastic-coated), stainless steel (for highly corrosive environments)

Force Transfer Bolts / Nuts: Carbon steel (hot-dip galvanized) or stainless steel (e.g., 35#, 1Cr18Ni9Ti)

Compensation Characteristics:

Compensation Method: Used only for length adjustment during installation and disassembly (minor displacement); rigidly connected during operation, does not absorb axial movement (unlike restrained expansion joints)

3. Operating Principle

Force Transfer Mechanism: When axial thrust is generated due to pressure changes or thermal expansion in the pipeline, the force is evenly distributed across the system via force transfer bolts, preventing concentrated stress on valves, pumps, and other equipment

Installation Adjustment: By adjusting the spacing between the expansion short pipe and both flanges, installation deviations in pipeline dimensions are compensated, facilitating on-site alignment of flange bolt holes

Sealing and Rigid Connection: After diagonally tightening the gland bolts, the sealing ring is compressed to form a seal; simultaneously, the bolts rigidly lock both flanges, ensuring mechanical force transmission without displacement

Hot Tags: Force Transfer Joint / Expansion Joint /