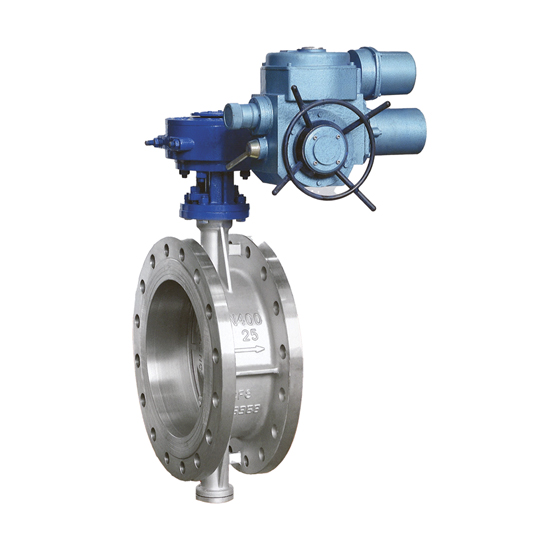

I. Product Overview

The grooved butterfly valve adopts a quick-connect grooved-end structure. Both ends of the valve body feature circular grooves that allow mechanical connection to pipelines via grooved couplings—eliminating the need for welding or threaded fittings. The stem and disc are designed either coaxially or eccentrically, depending on the sealing type, and are paired with soft seals (e.g., rubber) or hard seals (e.g., metal) to achieve reliable media sealing.

This butterfly valve is widely used in industrial and civil pipeline systems. It is suitable for media such as water, air, oil, and neutral gases, with operating temperatures ≤120℃ and working pressure ≤1.6 MPa. Typical applications include water supply and drainage, HVAC, chemical processing, and municipal engineering. The valve is primarily used to shut off or regulate fluid flow within pipelines.

II. Product Features

Grooved-End Connection Design Quick and easy installation and removal without the need for specialized welding equipment or threading. This significantly shortens construction time and reduces installation costs. The connection is reliably sealed and capable of withstanding axial thrust from the pipeline.

The sealing structure is flexible and can be configured with either soft or hard sealing materials depending on operating conditions: – Soft seals are ideal for low-pressure, ambient temperature, and clean media, offering excellent sealing performance – Hard seals are suitable for high-temperature, high-pressure, and particle-laden media, providing superior wear resistance

Robust Valve Body and Disc The valve body is made of ductile iron or cast steel, offering high strength and corrosion resistance. The disc is precision-machined with a smooth surface, minimizing flow resistance and ensuring strong flow capacity with low energy consumption.

Multiple Actuation Options Supports manual, electric, and pneumatic actuation. The valve operates smoothly and offers stable regulation performance, meeting various automation control requirements.

Compact Structure Small in size and lightweight, the valve occupies minimal pipeline space, making it ideal for installation in confined areas. It is easy to maintain, with interchangeable components that reduce long-term maintenance costs.

Wide Applicability Compatible with grooved piping systems of various diameters. Its strong adaptability makes it suitable for fluid control needs across multiple industries.

III. Main Standards

The valve’s design, performance, and installation comply with the following national standards:

• GB 5135.11-2019 – Automatic Sprinkler System – Part 11: Grooved Pipe Fittings • GB/T 12238-2008 – Flanged and Wafer Type Resilient Seated Butterfly Valves • GB/T 26146-2010 – Valve Flow Coefficient and Flow Resistance Coefficient Test Methods

Specific technical parameters and performance indicators should be based on the product’s factory-issued technical documentation.

热门标签: Butterfly Valve /