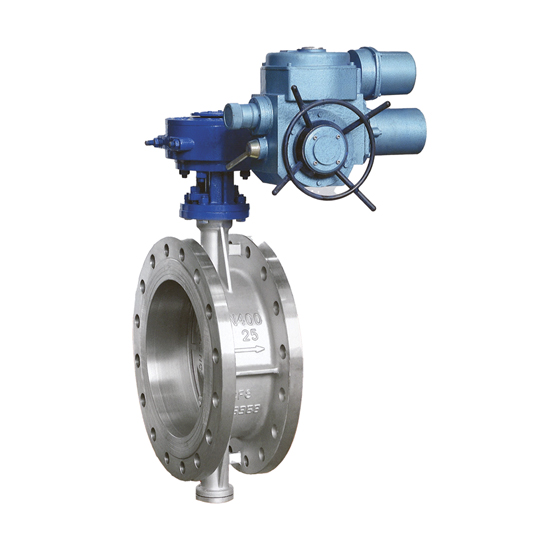

1. Product Overview

The stainless steel triple-offset metal-sealed butterfly valve features a precision-engineered J-shaped resilient sealing ring and a multi-layer metal sealing structure based on a three-dimensional eccentric design. This configuration ensures an ideal spatial movement trajectory of the sealing surfaces—free from friction and interference—while the carefully selected sealing materials guarantee excellent performance in terms of sealing integrity, corrosion resistance, high-temperature tolerance, and wear resistance.

This valve is widely used in industrial pipelines with media temperatures ≤425°C, including metallurgy, power generation, petrochemical, water supply and drainage, and municipal infrastructure. It is primarily designed for flow regulation and fluid shut-off.

2. Product Features

Triple-offset sealing structure minimizes wear between the seat and disc, providing a “tightening as it closes” sealing effect.

The valve body is made of stainless steel, combining the advantages of both metal and resilient sealing. It maintains excellent sealing performance under both low and high temperatures, with strong corrosion resistance and long service life.

The disc sealing surface is overlayed with cobalt-based hard alloy, offering superior wear resistance and extended durability.

Large-diameter discs adopt a truss structure for enhanced strength, increased flow area, and reduced flow resistance.

Bidirectional sealing capability allows installation without restrictions on flow direction or spatial orientation—can be mounted in any position.

The actuator can be installed in multiple positions (90° or 180° rotation), offering flexibility and ease of use for operators.

3. Applicable Standards

Design Standard: GB/T 12238

Face-to-Face Dimension: GB/T 12221

Flange Connection: GB/T 9113

Testing & Inspection: GB/T 13927

Product Marking: GB/T 12220

热门标签: