I. Valve Overview

1. Product Definition & Operating Principle

The centerline flanged resilient seated butterfly valve is a flow control device that operates by rotating the disc around a central stem axis (the stem, disc, and valve body share the same centerline). Its core features include:

Centerline Symmetry: The disc, stem, and body are coaxially aligned. During operation, the disc rotates without eccentric displacement, ensuring uniform contact between the sealing surface and the seat.

Resilient Sealing Design: The seat or disc edge is fitted with flexible sealing materials such as rubber (EPDM/NBR/VITON), PTFE, or composite elastomers. When closed, a soft sealing surface is formed, ensuring bidirectional zero leakage.

Flanged Connection: Both ends of the valve body feature standard flanges (compliant with GB/T 9113, ASME B16.5, etc.), allowing for quick pipeline installation and maintenance.

Operating Mechanism:

Opening: Counterclockwise rotation of the handwheel or actuator turns the disc to 90° (handle parallel to the pipeline), disengaging the disc from the seat and fully opening the passage.

Closing: Clockwise rotation brings the disc into contact with the seat. The elastic sealing material compresses and uses media pressure to compensate for minor deviations, achieving tight sealing.

Flow Regulation: The disc can be positioned at any angle between 0° and 90°, allowing for throttling control—ideal for clean fluid applications.

2. Typical Applications

Thanks to its low cost, bidirectional sealing, minimal flow resistance, and ease of operation, the centerline resilient butterfly valve is widely used in:

Municipal Water Systems: Shut-off and flow control for potable water, sewage, and circulating water pipelines.

HVAC Systems: Chilled water, cooling water, and hot water circulation lines.

Light Industrial Processes: Food & beverage (juice/dairy), pharmaceuticals, paper manufacturing (non-particulate fluids), and weakly corrosive chemical liquids (non-aggressive acids/alkalis).

Other Uses: Air, steam (≤180℃), oil, clean natural gas, and other non-particulate clean fluids for throttling or isolation.

3. Model Code Interpretation

Example: D41X-16Q

D: Butterfly valve type

4: Connection type (flanged)

1: Structure type (centerline resilient seated)

X: Sealing material (rubber; options include X - NBR, E - EPDM, V - VITON)

16: Nominal pressure (PN16, 1.6 MPa)

Q: Body material (ductile iron; other options: C - cast steel WCB, P - stainless steel CF8, R - stainless steel 316L)

Other common models:

D41E: Flanged centerline, EPDM seal (weather-resistant, ideal for outdoor water systems)

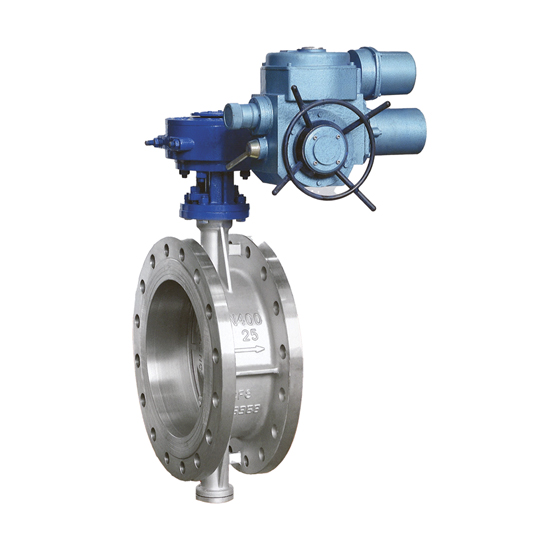

D941X: Electrically actuated flanged centerline butterfly valve

D371X: Wafer-type centerline (space-saving, installed between pipe flanges)

D641X: Pneumatically actuated type

II. Key Technical Parameters

1. Pressure Ratings

Nominal Pressure (PN): PN10 (1.0 MPa), PN16 (1.6 MPa), Class 150 (ASME standard)

Strength Test Pressure: 1.5 × PN (≥15 min, no deformation or leakage)

Sealing Test Pressure: 1.1 × PN (bidirectional, ≥15 min, no leakage)

2. Service Conditions

Operating Temperature Ranges:

NBR: -40℃ to +90℃ (excellent oil resistance, suitable for petroleum)

EPDM: -20℃ to +180℃ (strong weather resistance, preferred for water treatment)

VITON: -29℃ to +200℃ (resistant to high-temperature oils and chemicals)

PTFE-coated composite seal: -29℃ to +200℃ (for clean fluids only)

Applicable Media: Clean/dirty water, steam (≤180℃ short-term), air, natural gas, non-solvent oils, weakly corrosive liquids (e.g., diluted acids/alkalis, excluding strong oxidizers)

Body Materials: Ductile iron (QT450), gray cast iron (HT200), cast steel (WCB), stainless steel (CF8/CF8M)

Disc Materials: Nickel-plated ductile iron / nylon-coated, aluminum alloy, stainless steel (304/316), copper alloy

Stem Materials: Stainless steel (304/316), hardened steel 2Cr13; blowout-proof design ensures long-term reliability

3. Structural Dimensions

Nominal Diameter: DN50 to DN1200 (larger sizes available upon request)

Flange & Face-to-Face Dimensions: Compliant with GB/T 12221 (straight-through type) or international equivalents

Full Bore Design: Minimizes flow resistance; flow coefficient approaches that of straight pipe

III. Design Features & Advantages

1. Centerline Symmetry Benefits

Low Operating Torque: No eccentric friction loss; easy manual operation, especially for large diameters (DN ≤600)

Reliable Bidirectional Sealing: Elastic materials adapt to pressure fluctuations; installation direction is flexible (flow arrow is for optimal sealing life)

Compact & Cost-Effective: Flanged connection is more economical than metal-seated valves—ideal for budget-sensitive projects

2. Resilient Sealing Technology

Zero Leakage Guarantee: Rubber/NBR/EPDM materials achieve bidirectional zero visible leakage via interference fit and pressure-assisted sealing

Fire-Safe Backing: Metal-supported rubber seats (on select models) comply with API 607 / BS 6755 fire safety standards—temporarily block flame spread during fire

Replaceable Sealing Surfaces: Independent seat inserts or integrally vulcanized disc edges allow easy replacement after wear

3. Flanged Connection Convenience

Standardized Interfaces: Compatible with various flange standards (PN10/PN16 universal or custom flanges)

Easy Maintenance: Valve body separates from pipeline by removing bolts; disc and seat components are quickly serviceable

IV. Standards & Certifications

Design Standards: GB/T 12238 (general butterfly valve requirements), API 609 (resilient seated butterfly valve structure), ISO 5752 (face-to-face dimensions)

Testing Standards: GB/T 13927 (pressure testing), JB/T 9092 (resilient seal reliability), BS 6755 (fire test compliance)

Connection Standards: GB/T 9113 (flange dimensions), ASME B16.5 (ANSI flanges), EN 1092 (European flanges)

Special Certifications: WRAS (drinking water safety), NSF (food contact), ATEX (explosive atmosphere compliance)

Популярные теги: Butterfly Valve /