I. Product Overview

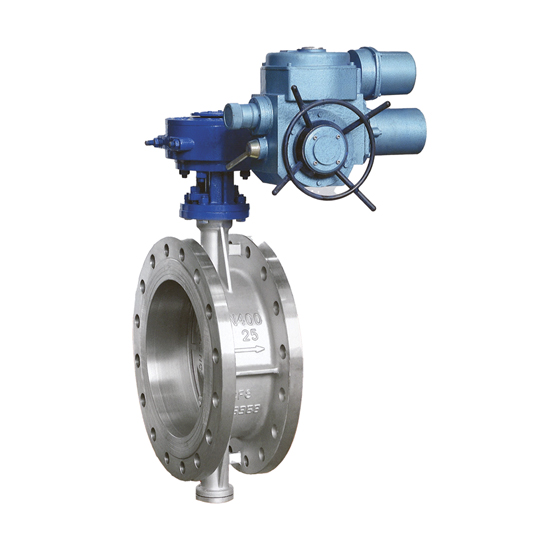

The stainless steel triple eccentric metal seated butterfly valve features a precision-engineered J-shaped resilient sealing ring and a multi-layer metal sealing structure based on a three-dimensional eccentric design. This geometry ensures an ideal spatial movement trajectory of the sealing surfaces, eliminating friction and interference between them. Combined with carefully selected sealing materials, the valve delivers outstanding performance in sealing reliability, corrosion resistance, high-temperature endurance, and wear resistance.

This butterfly valve is widely used in industrial pipelines with media temperatures up to ≤425℃, including metallurgy, power generation, petrochemical, water supply and drainage, and municipal infrastructure. It is primarily used for flow regulation and fluid shut-off.

II. Product Features

Triple Eccentric Sealing Structure Minimizes wear between the seat and disc. The sealing becomes tighter as the valve closes, ensuring reliable shut-off.

Stainless Steel Valve Body Combines the advantages of metal-to-metal and resilient sealing. Maintains excellent sealing performance under both low and high temperatures, with strong corrosion resistance and long service life.

Disc Sealing Surface Hardfaced with cobalt-based alloy, providing superior wear resistance and extended durability.

Large-Diameter Disc Design Utilizes a truss structure for enhanced strength, increased flow area, and reduced flow resistance.

Bidirectional Sealing Capability Installation is not limited by flow direction or spatial orientation. The valve can be installed in any position.

Multi-Position Actuator Mounting Actuator can be installed at various angles (90° or 180°), offering flexibility and ease of use for the operator.

III. Main Standards

Design Specification: GB/T 12238

Face-to-Face Dimension: GB/T 12221

Flange Connection: GB/T 9113

Testing & Inspection: GB/T 13927

Product Marking: GB/T 12220

Популярные теги: Butterfly Valve /