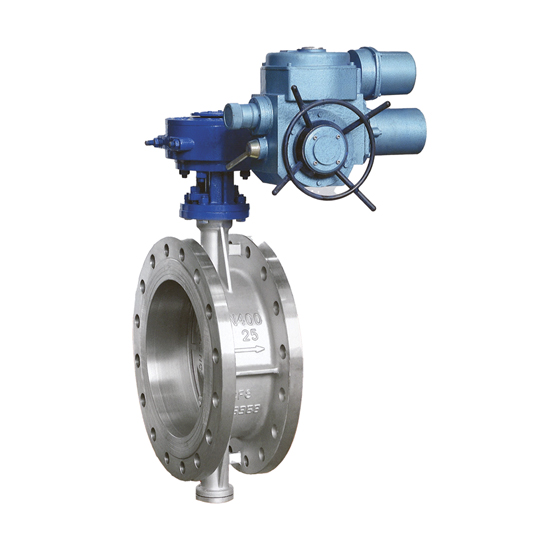

It adopts a precise J-shaped elastic sealing ring and a three-eccentric multi-layer metal hard sealing structure, which is widely used in industrial pipelines such as metal control, electric power, petrochemical industry, water supply and drainage, and municipal construction with a medium temperature ≤ 425°C, and is used to regulate flow and load and break fluids. The valve adopts three eccentric structures, the valve seat and the disc plate sealing surface are made of different hardness and stainless steel, with good corrosion resistance, long service life, the valve two-way sealing function, the product meets the national GB/T13927-92 valve pressure test standard. Welding butterfly valves, chemical industry, building materials, power stations, glass and other industries in ventilation, environmental protection engineering, etc

Product features:

1. It is designed and manufactured by a new structural form of welding between the middle line disc plate and the short structure steel plate, which is compact in structure, light in weight, easy to install, small flow resistance, large flow volume, avoids the influence of high temperature expansion, and is light in operation

2. There are no connecting rods, bolts, etc. inside, reliable work and long service life. It can be installed in multiple stations and is not affected by the flow direction of the medium

Use:

This butterfly valve is a non-hermetic butterfly valve, which is widely used in the production process of building materials, metallurgy, mining, electric power and other production processes with a nominal pressure of 0.1Mpa ≤ 300°C nominal pressure, which is used to connect, open and close or adjust the medium quality.

Structural features:

This butterfly valve system is designed and manufactured by a new structural form of welding between the middle line disc plate and the short structure steel plate, which is compact in structure, light in weight, easy to install, small flow resistance, large flow volume, avoids the influence of high temperature expansion, and is light in operation. There are no connecting rods, bolts, etc. in the body, reliable work and long service life. It can be installed in multiple stations and is not affected by the flow direction of the medium

Working principle:

Welding butterfly valve mechanism to make the disc plate rotate freely within 90° to achieve the purpose of opening and closing or adjusting the flow of the medium. At present, fluorine-lined butterfly valves and rubber-lined butterfly valves, as a component used to realize the on/off and flow control of pipeline systems, have been widely used in many fields such as petroleum, chemical industry, metallurgy, hydropower, etc. In the known butterfly valve technology, its sealing form mostly adopts a sealing structure, and the sealing material is rubber, polytetrafluoroethylene, etc. Due to the limitations of structural characteristics, it is not suitable for high temperature resistance, high pressure resistance, corrosion resistance, wear resistance and other industries. The existing butterfly valve is a three-eccentric metal hard seal butterfly valve, the valve body and valve seat are connected components, and the surface layer of the valve seat seal is welded with temperature-resistant and corrosion-resistant alloy materials. Multi-layer soft stack sealing ring fixed on the valve plate, this butterfly valve has high temperature resistance compared with the traditional butterfly valve, light operation, no friction in opening and closing, and compensates for the seal with the increase of the torque of the transmission mechanism when closing, which improves the sealing performance of the butterfly valve and prolongs the service life.

热门标签: