1. Valve Overview

1.1 Product Definition and Application

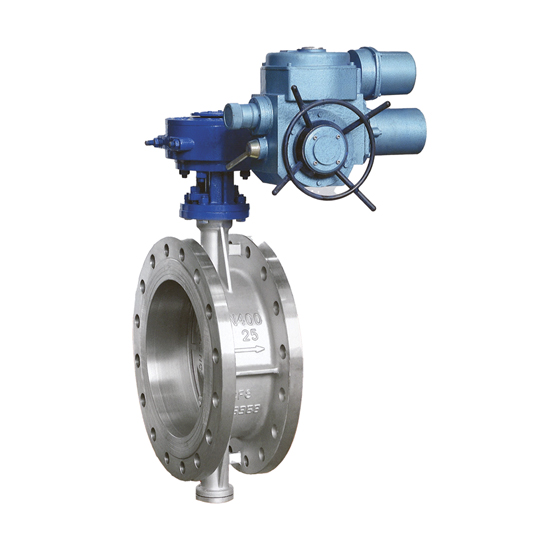

The metal-sealed butt-welded butterfly valve is designed to control or shut off flow by rotating the valve disc around an eccentric shaft. Its core feature is the triple-offset metal sealing structure:

Radial offset: The centerline of the disc’s sealing surface is offset from the seat centerline.

Axial offset: The disc’s rotation axis is offset from the seat centerline.

Conical angle offset: The sealing surface is inclined at a conical angle (typically 8–12°).

This geometry ensures zero friction between the disc and seat during opening and closing. Metal-to-metal contact occurs only at the final closing moment, forming a high-strength seal ideal for high-temperature, high-pressure, abrasive, corrosive, and particle-laden media.

Butt-welded connection: The valve ends feature beveled weld ends conforming to ASME B16.25 / GB/T 12224 standards, allowing direct welding to pipelines. This ensures permanent zero-leakage sealing, saves flange space, and facilitates insulation layer installation.

Typical Applications:

Petrochemical (cracking units, catalytic pipelines)

Coal chemical

Metallurgy (blast furnace gas, slurry transport)

Power generation (steam systems, desulfurization/denitrification)

Cement, mining, and district heating systems

1.2 Model Code Interpretation

Example: D363H

D: Butterfly valve type

3: Actuation method (worm gear)

6: Connection type (butt-welded)

3: Structure type (triple-offset metal seal)

H: Sealing material (Cr13 alloy steel)

Other common variants:

D663H: Pneumatic actuator, butt-welded

D963H: Electric actuator, butt-welded

Sealing options: Y (hard alloy), F (PTFE composite soft seal)

2. Technical Parameters

2.1 Pressure Ratings and Test Standards

Nominal pressure (PN): PN10 (1.0 MPa), PN16 (1.6 MPa), PN25 (2.5 MPa), PN40 (4.0 MPa), Class 150–2500 (ASME)

Strength test pressure: 1.5 × PN (≥15 minutes, no deformation or leakage)

Sealing test pressure: 1.1 × PN (≥15 minutes, no visible leakage); additional low-pressure sealing tests may be required for gas-solid mixtures (e.g., 0.6 MPa air-tightness test)

2.2 Operating Conditions

Temperature range:

Cr13/Y metal seal: –29°C to +425°C (short-term ≤550°C, e.g., steam systems)

Tungsten carbide overlay: –46°C to +650°C (extreme temperature service)

PTFE composite seal: –29°C to +200°C (clean fluids only)

Applicable media: Water, steam, oil, natural gas, slurry, ore pulp, fly ash, acids and alkalis (non-oxidizing), crystallized solutions, and other particle/fiber-laden fluids

Material options:

Body/Cover: Cast steel (WCB/A105), stainless steel (CF8/CF8M), sour service steel (NACE MR0175), low-temperature steel (LCB)

Disc: Wear-resistant alloy (2Cr13 nitrided / tungsten carbide overlay), duplex stainless steel (2205), hardened alloy steel

Seat: Spring-loaded floating seat with automatic wear compensation; metal-backed fire-safe design (API 607 / BS 6755 compliant)

2.3 Dimensions

Nominal diameter: DN40–DN4000

Weld bevel dimensions: ASME B16.25 / GB/T 12224

Face-to-face length: GB/T 12221 (straight-through type) or API 6D

Flow path: Full bore design minimizes flow resistance

3. Structure and Operating Principle

3.1 Triple-Offset Design Explained

First offset (radial): Disc sealing surface centerline offset from seat centerline to reduce friction

Second offset (axial): Disc rotation axis offset from seat centerline to ensure full disengagement during opening

Third offset (conical angle): Sealing surface inclined at 8–12°, creating a wedge effect during closing for enhanced sealing pressure

Advantages:

Frictionless operation reduces wear and extends service life

Metal wedge seal compensates for thermal expansion and pressure fluctuations

Fire-safe design ensures sealing even if PTFE fails in explosive environments

3.2 Key Components

Body: Cast or welded steel structure, butt-welded ends (no flanges), mid-flange sealed with flexible graphite

Disc (eccentric shaft assembly): Solid or hollow, sealing surface precision-ground or overlayed with wear-resistant alloy (e.g., tungsten carbide)

Seat: Spring-loaded floating design, dual-metal backing for long-term sealing reliability

Actuation: Handwheel, worm gear (torque-saving), electric/pneumatic actuator (remote control); stem supported by bearings with anti-static protection

3.3 Operating Mechanism

Opening: Counterclockwise rotation of the handwheel drives the disc to rotate around the eccentric shaft, fully disengaging from the seat (unobstructed flow)

Closing: Clockwise rotation gradually brings the disc into contact with the seat, forming a wedge-tight seal at the final moment—achieving bidirectional zero-leakage sealing

Position indication: Handle parallel to pipeline = fully open (0°); perpendicular = fully closed (90°); electric actuators use limit switches or feedback signals

4. Standards and Certifications

Design standards: GB/T 12238 (general butterfly valve requirements), API 6D (oil & gas pipelines), ASME B16.34 (pressure-temperature ratings)

Test standards: GB/T 13927 (general pressure test), JB/T 9092 (soft seal reliability), API 598 (fire test)

Connection standards: GB/T 12221 (face-to-face dimensions), ASME B16.25 (butt-weld ends)

Special certifications: API 607 / 6FA (fire-safe design), ISO 15156 (sour service), EN 1797-1 (oxygen compatibility)

热门标签: